Are you interested in the inspection process of LCD? This article will tell you the process of TX inspect LCD.

1.Professional QC team

We have 16 years of professional production experience in mobile phone spare parts and stable supply strength.

We have a complete range of products and strictly control the quality of high-quality products.

We are a factory with 200-300 employees and have a very professional and strict QC team. Before all employees take up their jobs, we will give them very comprehensive operation training to ensure that they are proficient before they can enter the production line.

2.Dust-free environment

All employees entering the production line must wear uniforms, hats and gloves as required, keep the environment clean and tidy, and reduce fingerprints on the LCD screen.

3. 9 steps to control the quality,reduce the damaga rate.

Install to test → Test Frame → Test LCD and touch → Assemble spare parts → Retest → Put protector film on → Pack into box → labelling → Check in to warehouse

Each LCD must be tested 3 times before shipment to ensure the quality standards of screen display and touch functions.

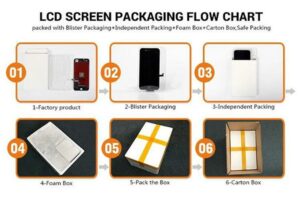

4.Packaging process

All products that have been tested one by one for many times will be transferred to the warehouse for packaging.

Each LCD will be individually covered with a plastic sponge protective film, then put into a box, and finally put into a sponge box.

Guaranteed to avoid the rush of transportation and to safe delivery to each customer.

If you have any questions please feel free to contact us.

GUANGZHOU TX ELECTRONIC TECHNOLOGY CO.,LTD.

Client Care

Wechat & Whatsapp: +86-19120668017

E-mail: txlcd@txlcd.com

Tel/Fax: +86-020-34021572

Website: www.txlcd.com

Address: Room 406-407, ZonJi Business Center, No.18-20 YanSha Road, Nanpu, Panyu District, Guangzhou, China

Leave A Comment

You must be logged in to post a comment.